2021 China New Design Flat Box Labeling Machine - FK616A Semi Automatic double-barrelled bottle Sealant Labeling Machine – Feibin

2021 China New Design Flat Box Labeling Machine - FK616A Semi Automatic double-barrelled bottle Sealant Labeling Machine – Feibin Detail:

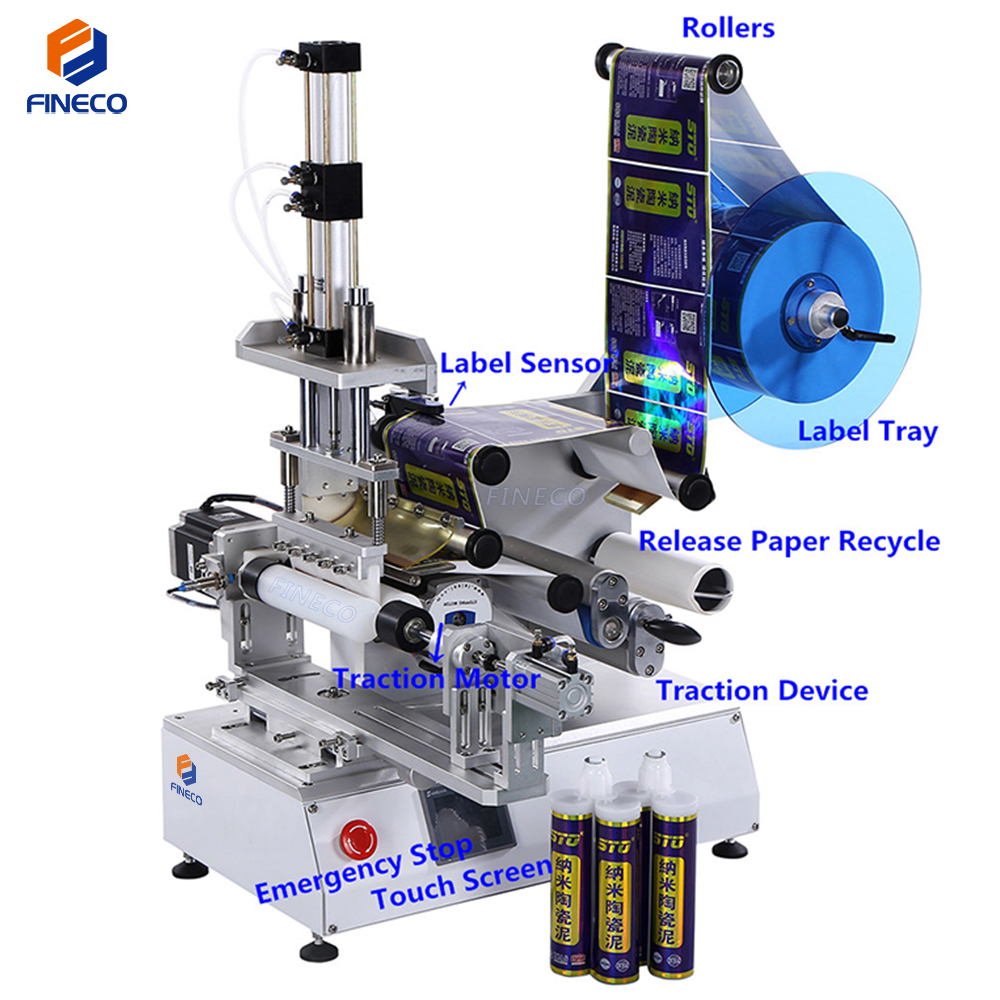

FK616A Semi Automatic Sealant Labeling Machine

You can set video sharpness in the lower right corner of the video

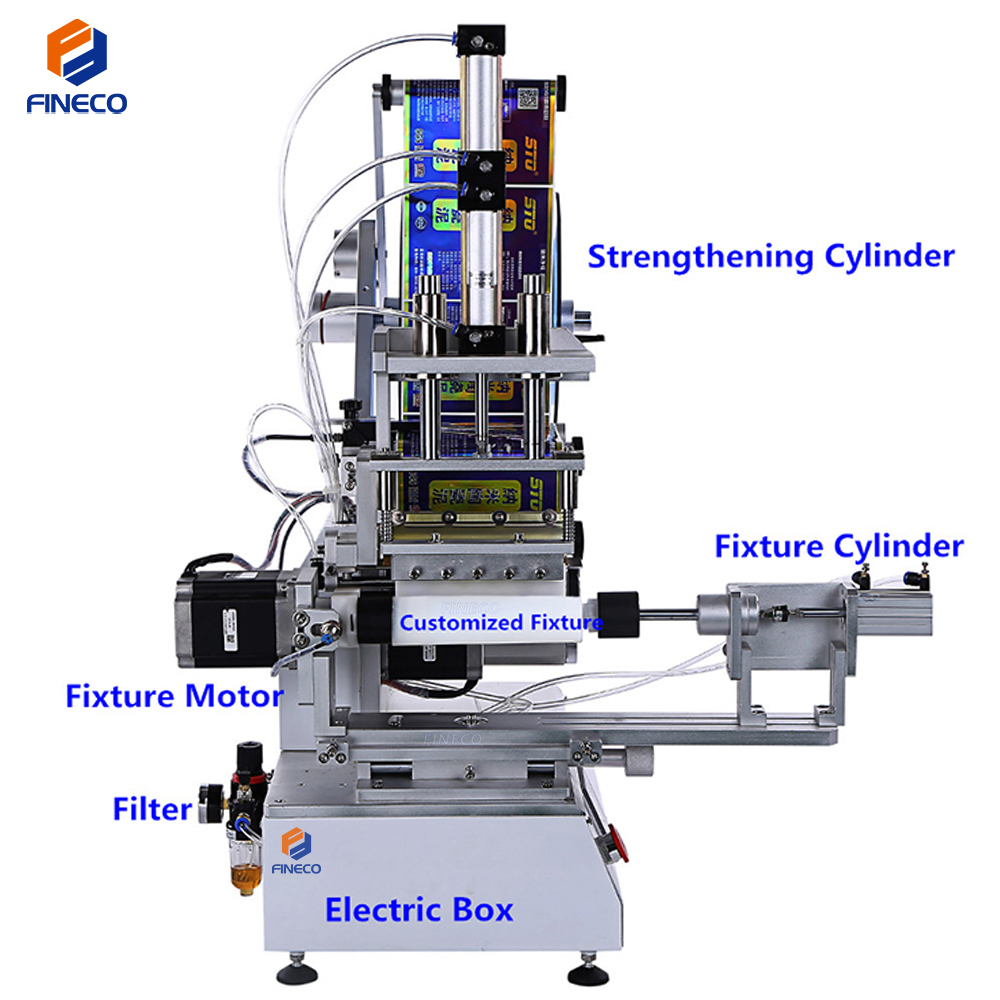

Basic Use:

④ FK616A Adjust method is simple: 1.Adjust the height of the pressing plate and the position of the cylinder according to the size of the product,let the plate presses the product. 2.Adjust the position of sensor let a piece of label can be entire come out.3.Adjust the position of the product and the first stage labeling length, let the first stage label can be pressed between the two tubes of the produce by the press plate, the error of labeling is not visible to the naked eye , it is a good helper of the sealant labeling.

⑤ FK616A floor space about 0.56 stere.

⑥ Machine Support Customization.

Technical Parameters:

| Parameter | Date |

| Label Specification | Adhesive sticker,transparent or opaque |

| Labeling Tolerance | ±0.5mm |

| Capacity(pcs/min) | 15~25 |

| Suit bottle size(mm) | L:20~200 W:20~150 H:0.2~120;Can be customized |

| Suit label size(mm) | L:15-200;W(H):15-130 |

| Machine Size(L*W*H) | ≈830*720*950(mm) |

| Pack Size(L*W*H) | ≈1180*750*1100(mm) |

| Voltage | 220V/50(60)HZ;Can be customized |

| Power | 660W |

| N.W(KG) | ≈45.0 |

| G.W(KG) | ≈67.5 |

| Label Roll | ID:Ø76mm; OD:≤240mm |

| Air Supply | 0.4~0.6Mpa |

Working Principle:

1.Press the switch after the product is placed in the designated position, the machine will clamp the product and pull-out the label.

2.The press-plate on the top of machine will press the label onto the product and then the machine will make the product roll until the labeling is finished

3.Last release the product and the machine will automatic restore , a labeling process is completed.

Label Specification:

①Applicable labels: sticker label, film, electronic supervision code, bar code.

②Applicable products: Products that are required to be labeled on flat, arc-shaped,round, concave, convex or other surfaces.

③Application industry: Widely used in cosmetics, food, toys, chemical, electronics, medicine and other industries.

④Application examples: shampoo flat bottle labeling, packaging box labeling, bottle cap, plastic shell labeling, etc.

Product detail pictures:

Related Product Guide:

We try for excellence, service the customers", hopes to be the most effective cooperation workforce and dominator company for staff, suppliers and shoppers, realizes price share and ongoing marketing for 2021 China New Design Flat Box Labeling Machine - FK616A Semi Automatic double-barrelled bottle Sealant Labeling Machine – Feibin , The product will supply to all over the world, such as: Slovakia, Leicester, Iraq, We're your reliable partner in the international markets of our products and solutions. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade solutions in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market. We're willing to cooperate with business friends from at home and abroad, to create a great future. Welcome to Visit our factory. Looking forward to have win-win cooperation with you.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.