Factory Outlets Batch Print Labgling Machine - FK605 Desktop Round/Taper Bottle Positioning Labeller – Feibin

Factory Outlets Batch Print Labgling Machine - FK605 Desktop Round/Taper Bottle Positioning Labeller – Feibin Detail:

FK605 Desktop Round/Taper Bottle Positioning Labeller

You can set video sharpness in the lower right corner of the video

| Parameter | Date |

| Label Specification | Adhesive sticker,transparent or opaque |

| Labeling Tolerance(mm) | ±1 |

| Capacity(pcs/min) | 20 ~ 45 |

| Suit product size(mm) | φ25~φ120; H:25~150; Can be customized |

| Suit label size(mm) | L:20 ~ 380; W(H):20 ~ 130 |

| Machine Size(L*W*H)(mm) | ≈1260*970*890 |

| Pack Size(L*W*H)(mm) | ≈1280*1000*920 |

| Voltage | 220V/50(60)HZ;Can be customized |

| Power(W) | 120 |

| N.W(KG) | ≈100 |

| G.W(KG) | ≈130 |

| Label Roll(mm) | ID:>76; OD:≤260 |

Label Production Requirements

1. The gap between the label and the label is 2-3mm;

2. The distance between the label and the edge of the bottom paper is 2mm;

3. The bottom paper of the label is made of glassine, which has good toughness and prevents it from breaking (to avoid cutting the bottom paper);

4. The inner diameter of the core is 76mm, and the outer diameter is less than 280mm, arranged in a single row.

The above label production needs to be combined with your product. For specific requirements, please refer to the results of communication with our engineers!

Labeling Process:

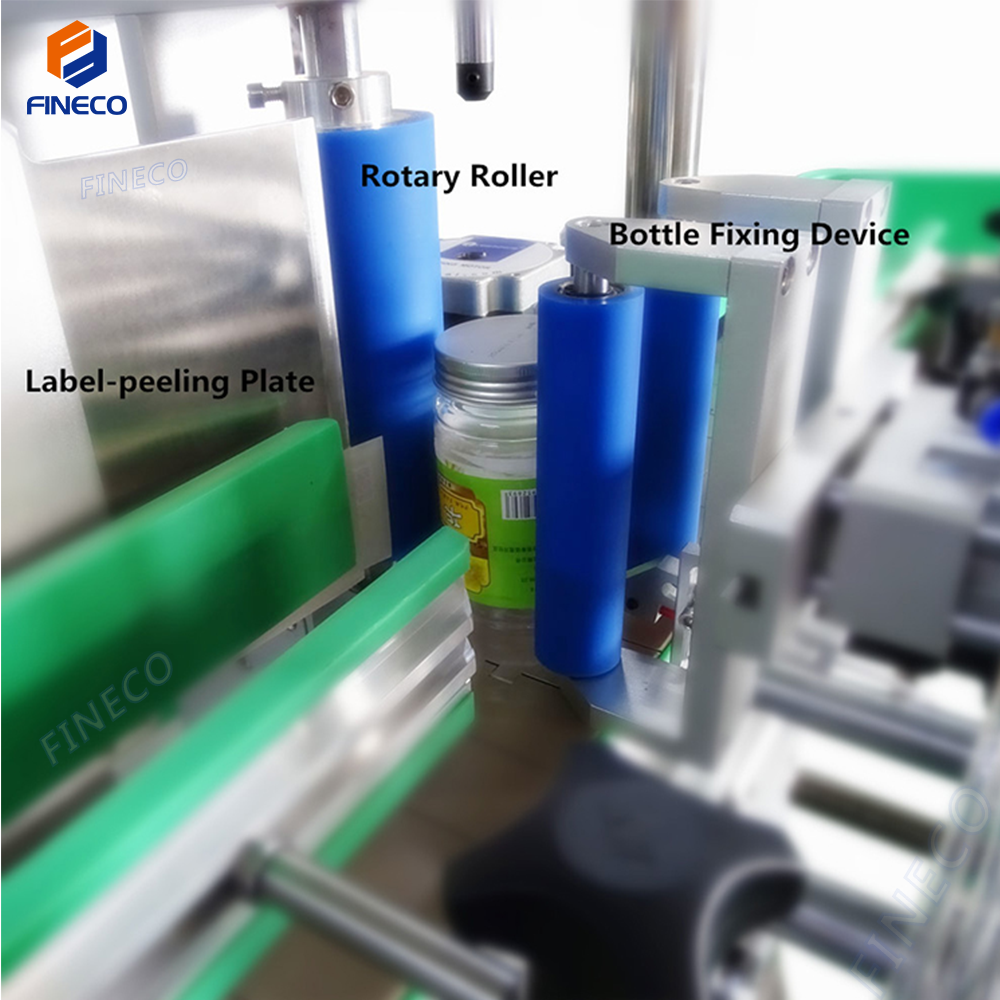

Put products in the feeding device → The products are transmitted by the conveyor belt → The product sensor detects the product→The PLC receives the product signal and let labeling motor action→ cylinder fixed the product and labeling

Features:

1 ) Control System: Japanese Panasonic control system, with high stability and extremely low failure rate.

2 ) Operation System: Color touch screen, directly visual interface easy operation.Chinese and English available . Easily to adjust all electrical parameters and have counting function, which is helpful for production management.

3) Detection System: Using German LEUZE/Italian Datalogic label sensor and Japanese Panasonic product sensor, which are sensitive to label and product, thus ensure high accuracy and stable labeling performance. Greatly saves labor.

4) Alarm Function: The machine will give an alarm when problem occur, such as label spill, label broken, or other malfunctions.

5) Machine Material: The machine and spare parts all use material stainless steel and anodized senior aluminum alloy, with high corrosion resistance and never rust.

6) Equip with a voltage transformerto adapt to local voltage.

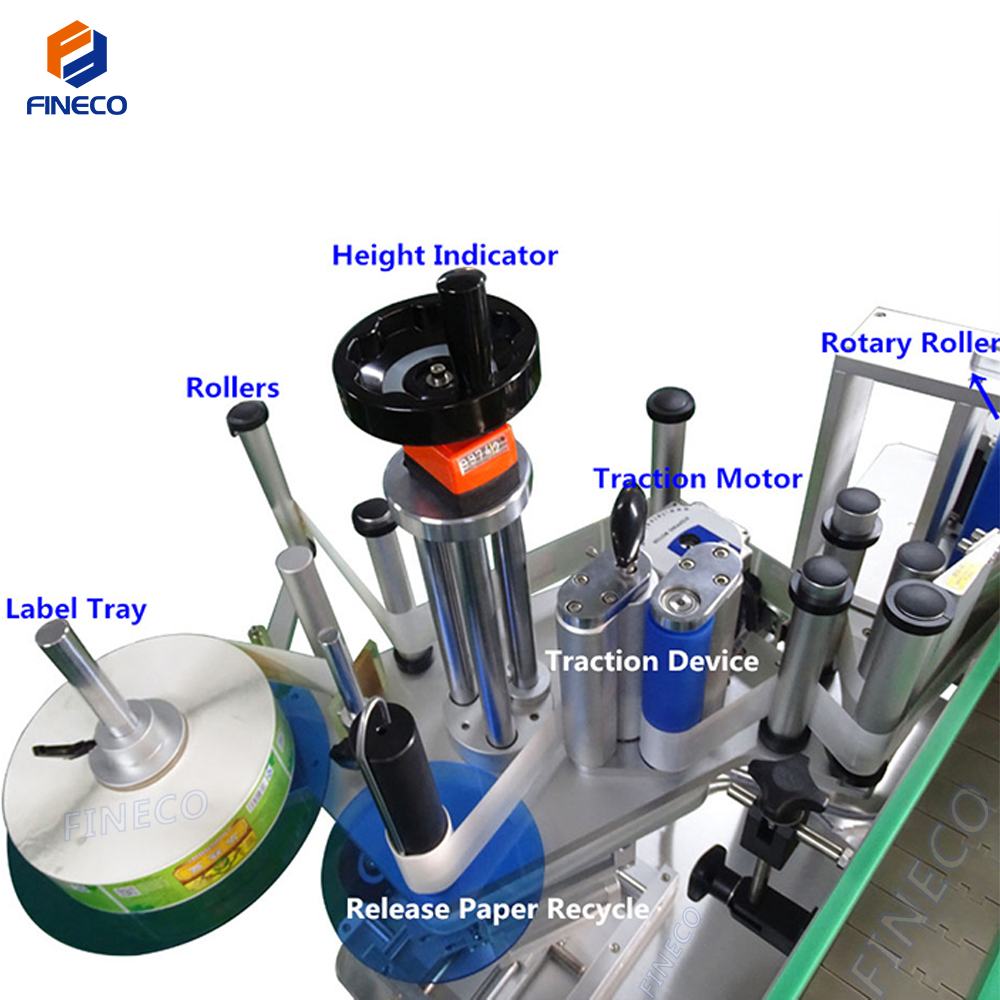

Product detail pictures:

Related Product Guide:

Using a complete scientific top quality management program, great high-quality and fantastic religion, we win great track record and occupied this area for Factory Outlets Batch Print Labgling Machine - FK605 Desktop Round/Taper Bottle Positioning Labeller – Feibin , The product will supply to all over the world, such as: Dominica, Southampton, Swedish, We also have the strong ability of integration to supply our best service, and plan to build the warehouse in the different countries around the world, that will be more conveniently to service our customers.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!