Free sample for Soda Filling Machine - FK 6 Nozzle Liquid Filling Capping Labeling Machine – Feibin

Free sample for Soda Filling Machine - FK 6 Nozzle Liquid Filling Capping Labeling Machine – Feibin Detail:

FK 4 nozzle liquid filling capping labeling machine

You can set video sharpness in the lower right corner of the video

Machine Description

Applied Range: And material contact material imported 304 l material, no particles can be all kinds of corrosive resistant low viscosity fluid, such as: all kinds of reagents (medicine oil, wine, alcohol, eye drops, syrup), chemicals (solvents, acetone), oil (feed oil, essential oils, cosmetics (toner, makeup water, spray), food (high temperature resistant to 100 degrees, such as milk, soy milk), beverages, fruit juice, fruit wine, spices, soy sauce vinegar, sesame oil, etc without granular liquid;High and low foam liquid (nursing liquid, cleaning agent)

Filling of food, medical,cosmetic,chemical and other bottle liquids. Plus: wine, vinegar, soy sauce, oil, Water, etc.

Widely used in food, cosmetic, chemical, pharmaceutical and other industries.It can work alone or connect to production line.

Support customization.

Six – nozzle magnetic pump automatic filling line

| Six – head magnetic pump automatic filling line | |

| parameter configuration: | |

|

Metering method |

Time and speed adjustment, suitable for almost all liquid products. |

|

Container size |

Phi :20-30-350 mm; H:160mm |

|

Packaging weight |

>= 2g |

|

Packing precision |

Packing weight≤100g deviation≤±1g;Packing weight>100g deviation≤±1%(test is based on water) |

|

packing speed |

25-60 cans/min |

|

power supply |

single-phase 220 v, 50 hz |

|

Machine weight |

150 kg |

|

machine power |

1Kw |

|

machine volume |

2000×1000×1400mm |

|

Magnetic pump flow range |

10-5500 ml/min (take water as an example).Each working pump is separately controlled.The test is based on sending sample bottles. |

|

Filling volume |

10-2000ml |

Fully Automatic Multi-function Cap Screwing Machine

applied range: This equipment is used in food and beverage, pesticide and fertilizer, chemical industry plastic bottle glass bottle automatic hanging cap screw, straight line hanging cap preturning cap, can be applied to a variety of bottle, bottle change simple and fast, high production efficiency.

| Fully automatic multi-function cap screwing machine | |

| technical parameters: | |

| Model | HM – GJC – 16 |

| Suitable cap shape | Plastic, metal round cover, pump head cover, duck mouth cover, etc |

| sealing height | 30-300CM |

| Sealing diameters | 16-70CM |

| production speed | 20-50 bottles per minute |

| operating voltage | AC220V 60Hz |

| working air pressure | 0.4-0.6 MPa |

| length width and height | 1920*74*160CM |

| package size | 2002*82*176CM |

| weight | 140KGS |

Automatic electromagnetic induction aluminum foil sealing machine

Features: composite electromagnetic induction aluminum foil sealing technology is contemporary international recognized advanced seal technology, the non-contact heating to adapt to the characteristics of plastic (PP, PVC, PET, ABS, HDPE, PS, DURACON) glass bottles and various sealing compound plastic hose and so on, is the pharmaceutical, food, oil, cosmetic, household, agrochemical bottled sealing the most advanced technology, walk in the forefront of industry technology level core elements adopt international famous brand, products more strict inspection, so the quality is stable and reliable.

| Automatic electromagnetic induction aluminum foil sealing machine | |

| parameter: | |

| Device model | XSY-2300s |

| conveyor belt speed | 0-12.5 m/min |

| Sealing diameter | 0-12.5 m/min |

| sealing speed | 0-200 bottles/min |

| voltage | AC220V50/60Hz |

| Cooling mode | Air cooling |

| power | 1300~2800W Optional |

| packing size | 850X250X1370MM |

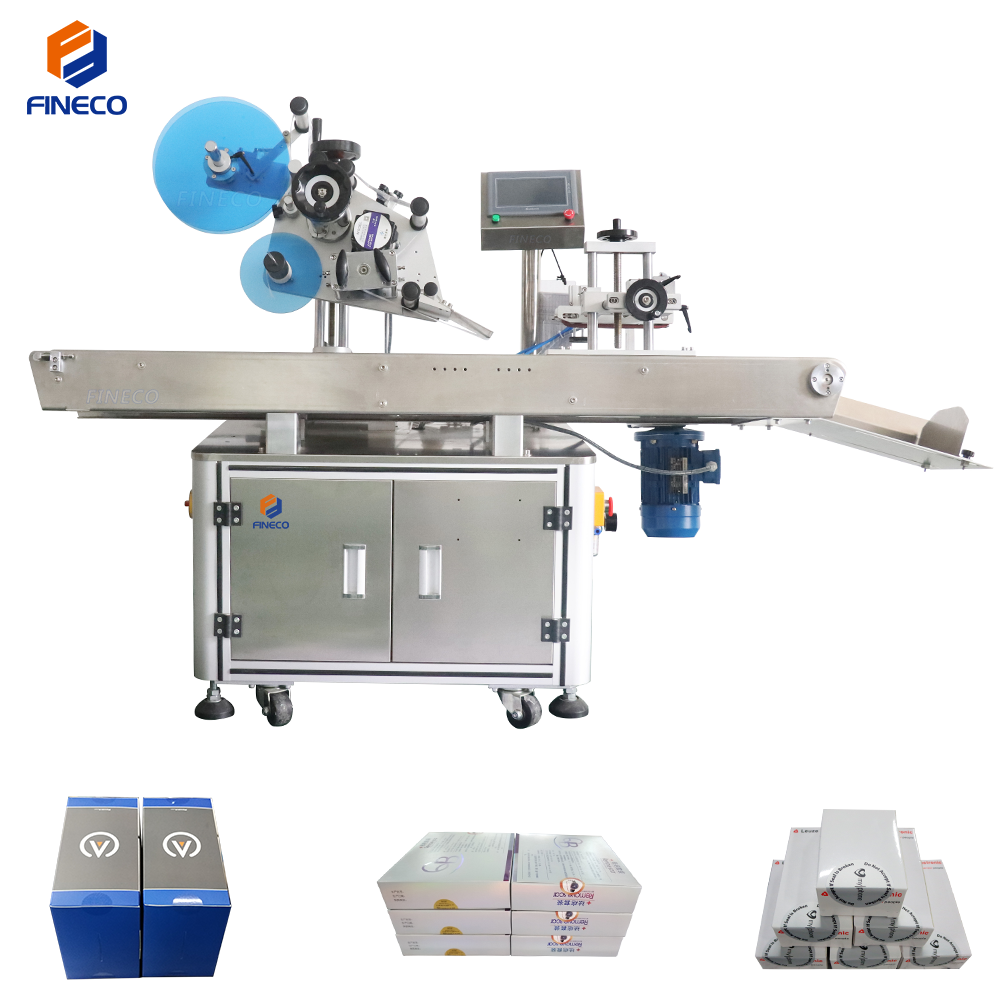

Automatic round bottle labeling machine

Suitable for round bottle labeling, can do single-labeling and double labeling, the labeling position can beadjusted casily. Widely used in cosmetics, food, pharmaceuticals, disinfectant and other industries.

| Automatic round bottle labeling machine | |

|

Parameter |

Data |

|

Label Specification |

adhesive sticker, transparent or opaque |

|

Labeling Tolerance |

±1mm |

|

Capacity(pcs/min) |

25 ~ 60 |

|

Suit bottle size(mm) |

Ø25~Ø120;Can be customized |

|

Suit label size(mm) |

L: 20-290; W(H): 20-130 |

|

Machine Size(L*W*H) |

≈1935*1250*1470 (mm) |

|

Pack Size(L*W*H) |

≈1950*1280*1500 (mm) |

|

Voltage |

220V/50(60)HZ;Can be customized |

|

Power |

865W |

|

N.W (KG) |

≈185 |

|

G.W(KG) |

≈360 |

|

Label Roll |

ID: Ø76mm;OD:≤260mm |

|

Air Supply |

0.4~0.6Mpa |

| Basic Application

|

*For all kinds of cylindrical,tapered objects labeling, such as xylitol, cosmetics bottles, wine bottles.. *Can do One Label Wrapping Around Labeling,Two Labels in Front and Back Side Labeling,and Orientation Labeling. *Widely used in food, cosmetic, chemical, pharmaceutical and other industries.It can work alone or connect to production line. *Date printer can be added to print production date,batch lot and expiry date while labeling. *Support customization. |

Product detail pictures:

Related Product Guide:

Sticking towards the theory of "Super Good quality, Satisfactory service" ,We are striving to become a superb business enterprise partner of you for Free sample for Soda Filling Machine - FK 6 Nozzle Liquid Filling Capping Labeling Machine – Feibin , The product will supply to all over the world, such as: Moscow, Salt Lake City, Austria, We've a skilled sales team, they have mastered the best technology and manufacturing processes, have years of experience in foreign trade sales, with customers able to communicate seamlessly and accurately understand the real needs of customers, providing customers with personalized service and unique merchandise.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.