OEM/ODM China Bottle Plastic Shrink Wrap Machine - Full Automatic L Type Sealing and Cutting Machine – Feibin

OEM/ODM China Bottle Plastic Shrink Wrap Machine - Full Automatic L Type Sealing and Cutting Machine – Feibin Detail:

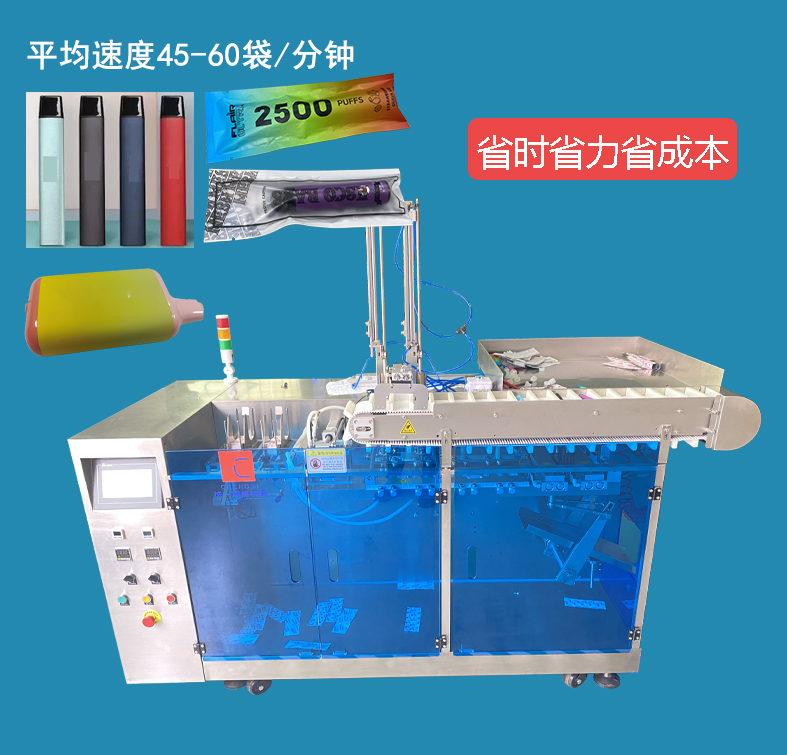

Full Automatic L Type Sealing and Cutting Machine

As a supporting equipment, Automatic L-type sealing and cutting machine is suitable for shrinking packaging of large quantities in software, food, cosmetics, printing, pharmaceutical, beverage, hardware and other industries.

The performance characteristics of the automatic L-shaped sealing and cutting machine: The automatic L-shaped sealing and cutting machine is a fully automatic unmanned operation sealing and cutting machine. The automatic feeding, sealing, cutting and output are automatically completed without manual assistance. The automatic film feeding and punching device, the manually adjusted film guide system, and the manually adjusted feeding and conveying platform are suitable for products of different widths and heights, realizing one machine to meet various sizes of packaging items. The L-type automatic sealing and cutting machine is used in conjunction with the shrinking machine.

The difference between this machine and the semi-automatic L-shaped sealing and cutting machine is: the electro-mechanical induction, automatic film feeding, and the semi-automatic sealing and cutting machine manual feeding.

Product advantages: The sealing and cutting knife adopts DuPont Teflon-coated anti-sticking and high-temperature resistant aluminum alloy knife, and the surface coating adopts the American DuPont Fron high-temperature and anti-sticking material to ensure that the sealing does not crack. One set of vertical detection, easy to switch, easy to complete packaging and automatic feeding for thin or small products, and the length can also be automatically adjusted by the combination of photoelectric and timer; equipped with induction motor, automatically reeling waste; when packaging When the size is changed, the adjustment is very simple. There is no need to change the mold and the bag device. The specially designed film up and down synchronization mechanism can correct the deviation of the film. The easy-to-tear function can be added according to the customer’s requirements.

Basic Characteristics:

1 Adopt L type sealing system.

2.Front and back conveyor adopt brake motor to avoid product forward rush because of belt stop’s inertia.

3.Advanced waste film recycling system.

4.Man-Machine interface controller, easy operation.

5.Packing quantity counter function.

6.High strength sealing integrated, sealing more fastness and exquisite.

Label Production Requirements

1. The gap between the label and the label is 2-3mm;

2. The distance between the label and the edge of the bottom paper is 2mm;

3. The bottom paper of the label is made of glassine, which has good toughness and prevents it from breaking (to avoid cutting the bottom paper);

4. The inner diameter of the core is 76mm, and the outer diameter is less than 280mm, arranged in a single row.

Parameter:

| Model | HP -4525 | Power Supply |

380V、3∮、50-60Hz |

| Power | 10kw | Packing Size | L800×W300×H150mm |

| Furnace Chamber Size | L1000×W450×H250mm | Packing Speed | 15-20pcs/min |

| Maximum Electricity | 32A | Net Weight | 220kg |

| Device Dimensions | L1372X W770 X H1560mm |

Structures:

Product detail pictures:

Related Product Guide:

To become the stage of realizing dreams of our employees! To build a happier, more united and extra professional workforce! To reach a mutual advantage of our prospects, suppliers, the society and ourselves for OEM/ODM China Bottle Plastic Shrink Wrap Machine - Full Automatic L Type Sealing and Cutting Machine – Feibin , The product will supply to all over the world, such as: United Arab Emirates, Ghana, Indonesia, The company has numbers of foreign trade platforms, which are Alibaba,Globalsources,Global Market,Made-in-china. "XinGuangYang" HID brand products sell very well in Europe, America, Middle East and other regions more than 30 countries.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.