Trending Products Printer And Label Maker - FK807 Automatic Horizontal Round Bottle Labeling Machine – Feibin

Trending Products Printer And Label Maker - FK807 Automatic Horizontal Round Bottle Labeling Machine – Feibin Detail:

FK807 Automatic Horizontal Round Bottle Labeling Machine

Machine Description

The FK807 labeling machine can realize full-week labeling and half-week labeling, as well as double label labeling on the front and back of the product, and the spacing between the front and back labels can be adjusted.

Work Process

working principle: The PLC processes product signal and label signal, then outputs signal to the traction motor to start labeling.

Labeling Process: Put products in the feeding device→ The products are separated one by one → The products are transmitted by the conveyor belt → The product sensor detects the product→ PLC receives the product signal and start labeling→ the conveyor belt send the labeled products to the collecting plate.

FK807 has additional functions to increase options:

① Optional automatic rotary bottling machine.

② It can be directly connected to the production line to realize automatic bottling and improve production efficiency.

③ The optional ribbon coding machine can be added to the label head, and the production batch, production date and expiration date can be printed at the same time. Reduce packaging procedures and greatly improve production efficiency.

④ Automatic feeding function (combined with product consideration);

⑤ Automatic material collection function (combined with product consideration);

⑥ Increase labeling device;

The adjustment method of FK807 is simple. It adopts the sponge labeling method, which can be labeled according to the product positioning. The labeling accuracy is high, the quality is good, and the speed is fast. It is difficult to see the error with the naked eye. It is the best choice for high-yield products.

FK807 covers an area of approximately 2.22 cubic meters.

Support custom labeling machine according to the product.

Label Production Requirements

1. The gap between the label and the label is 2-3mm;

2. The distance between the label and the edge of the bottom paper is 2mm;

3. The bottom paper of the label is made of glassine, which has good toughness and prevents it from breaking (to avoid cutting the bottom paper);

4. The inner diameter of the core is 76mm, and the outer diameter is less than 280mm, arranged in a single row.

The above label production needs to be combined with your product. For specific requirements, please refer to the results of communication with our engineers!

Technical Parameters

◆ Labeling accuracy (mm): ±1mm(errors caused by product and label are not concerned)

◆ Labeling speed (pcs / min):100~300pcs/min(influenced by the size of the product and label)

◆ Applicable Product Diameter:φ10mm~φ30mm; (We can make it according to your sample diameter)

◆ Suitable label size(mm): length: 20mm~250mm; Width:20mm~110mm

◆Applicable power supply: 220V/50HZ

◆ Weight (kg): about 200kg

◆ Applicable standard roll Inner diameter (mm): φ76mm

◆ Applicable standard roll Outer diameter (mm): φ300mm

◆Power(W): 940W

◆ Device dimensions (mm) (L × W × H): about 2100mm × 750mm ×1400mm

| Parameter | Data |

| Label Specification | adhesive sticker, transparent or opaque |

| Labeling Tolerance | ±lmm |

| Capacity(pcs/niin) | 100 ~300 |

| Suit bottle size(mni) | 010 ~ 030;Can be customized |

| Suit label size(mm) | L: 20-290; W(H): 20-130 |

| Machine Sizc(L*W*H) | ^2100*720*1450 (mm) |

| Pack Size(L*W*H) | ^2010*750*1730 (mm) |

| Voltage | 220V/50(60)HZ;Can be customized |

| Power | 700W |

| N.W (KG) | Q185 |

| G.W(KG) | Q356 |

| Label Roll | ID: 076mm;OD:<26Omm |

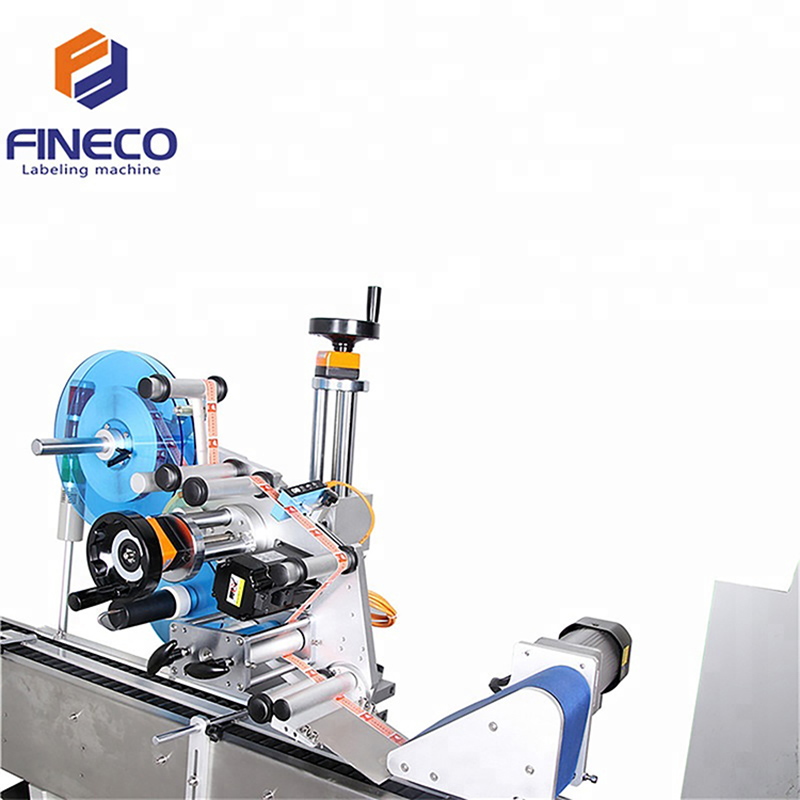

Structures:

| No. | Structure | Function |

| 1 | Feeding Device | separate and feed products. |

| 2 | Conveyor | transmit product. |

| 3 | Double Side Guardrails | keep the bottles goes straightly, can be adjusted according to the diameters of the bottles. |

| 4 | Labeling Head | core of the labelerzincluding label-winding and driving structure. |

| 5 | Touch screen | operation and setting parameters |

| 6 | Rotary Belt | drive products to rotate while labeling wrap around. |

| 7 | Collection Plate | collect the labeled products. |

| 8 | Electric Box | place electronic configurations |

| 9 | Main Switch | |

| 10 | Emergency Stop | stop the machine if it runs wrong |

| 11 | Adjusters | used to adjust labeling position |

Features:

1 ) Control System: Japanese Panasonic control system, with high stability and extremely low failure rate.

2 ) Operation System: Color touch screen, directly visual interface easy operation.Chinese and English available. Easily to adjust all electrical parameters and have counting function, which is helpful for production management.

3) Detection System: Using German LEUZE/Italian Datalogic label sensor and Japanese Panasonic product sensor, which are sensitive to label and product, thus ensure high accuracy and stable labeling performance. Greatly saves labor.

4) Alarm Function: The machine will give an alarm when problem occur, such as label spill, label broken, or other malfunctions.

5) Machine Material: The machine and spare parts all use material stainless steel and anodized senior aluminum alloy, with high corrosion resistance and never rust.

6) Equip with a voltage transformerto adapt to local voltage.

Product detail pictures:

Related Product Guide:

The organization keeps on the procedure concept "scientific management, high quality and efficiency primacy, purchaser supreme for Trending Products Printer And Label Maker - FK807 Automatic Horizontal Round Bottle Labeling Machine – Feibin , The product will supply to all over the world, such as: Ghana, Malawi, Algeria, Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!